B&R Machine and Gear Corporation specializes in manufacturing direct replacement gearing for a wide range of industrial markets. With the capacity to produce right-angle gears up to 80″ in diameter, B&R considers themselves part of an elite group who is able to offer such sizable bevel gearing.

B&R Machine and Gear Corporation specializes in manufacturing direct replacement gearing for a wide range of industrial markets. With the capacity to produce right-angle gears up to 80″ in diameter, B&R considers themselves part of an elite group who is able to offer such sizable bevel gearing.

“While we have historically focused our efforts and reputation on our ability to manufacture large bevel gears, some of our customers may be surprised to know we also manufacture parallel axis gears up to 126″ in diameter,” said Michelle Maddox, B&R’s sales and business development manager.

Maddox is the granddaughter of founders Bennie L. and Doretta Boxx, who, in 1974, set up a small specialty job shop in the family’s garage. With the purchase of a single honing machine, B&R Machine and Gear — originally known as B&R Bevel Gears — began servicing the power transmission industry with replacement and repair parts. The company’s first purchased facility was in Addison, Illinois, and with the addition of four more machines and help from Ben’s entire family, B&R continued to prosper.

In 1978, while visiting his hometown, Ben invested in a second facility in Sharon, Tennessee. His son, Bennie Jr., established B&R Machine and Gear and maintained operations in the Sharon facility until 1980 when the two businesses consolidated and moved permanently to Tennessee.

In 1978, while visiting his hometown, Ben invested in a second facility in Sharon, Tennessee. His son, Bennie Jr., established B&R Machine and Gear and maintained operations in the Sharon facility until 1980 when the two businesses consolidated and moved permanently to Tennessee.

Through the years, B&R has continued to be a family-owned and operated business with significant contributions from Ben’s wife, children, grandchildren, and in-laws, many of whom have served the company since its inception and still today.

“I am always honored and excited to tell our all-American story,” Maddox said. “The fact that my grandparents started with very little and took such risks to better their family is all the motivation I need to work as hard as they did to help grow this company.”

An integral component to operating a successful business is employing the right people.

An integral component to operating a successful business is employing the right people.

“Trusting your management and fellow co-workers is vital to success,” Maddox said. “We’re very lucky to not have to overcome any trust issues or motivational roadblocks. Because key positions are held by family members, it’s a given that each of us are exuding 110-percent effort and that we’re all here for the same common goal.”

B&R’s main customers are gearbox repair facilities serving a multitude of industrial markets worldwide including power transmission, pulp and paper, sugar, refinery, steel, and marine industries. The company is able to perform each production process in-house, from engineering to final inspection and delivery.

Initial requests for a part begins with the engineering team who can provide design consultation, assessments, recommendations, and reverse engineering services for all types of gears, from existing parts to prototypes. No matter how broken or worn the gear might be, B&R’s engineer can design and develop CAD drawings with minimal information, even if all you have left is one single tooth. And that’s exactly what happened recently as Maddox recalls the time she received a gear tooth in the mail.

Initial requests for a part begins with the engineering team who can provide design consultation, assessments, recommendations, and reverse engineering services for all types of gears, from existing parts to prototypes. No matter how broken or worn the gear might be, B&R’s engineer can design and develop CAD drawings with minimal information, even if all you have left is one single tooth. And that’s exactly what happened recently as Maddox recalls the time she received a gear tooth in the mail.

“You would be amazed with the unusual scenarios that occur day-to-day,” Maddox said. “I recently received an envelope in the mail that read ‘Tooth Enclosed.’ I was certainly taken aback. Our customer indicated that’s all he had left. Word-of-mouth, thankfully, led him to us. After many discussions with him to better understand the application, our engineer was able to draw a physical part from a single tooth. And that’s pretty incredible. I may be biased considering our engineer, Terry Boxx Jr., is also family, but I can’t speak enough on his knowledge and expertise. He really saved the day on that one. Retelling the story about the time the guy sent us a tooth in the mail makes for pretty interesting family get-togethers.”

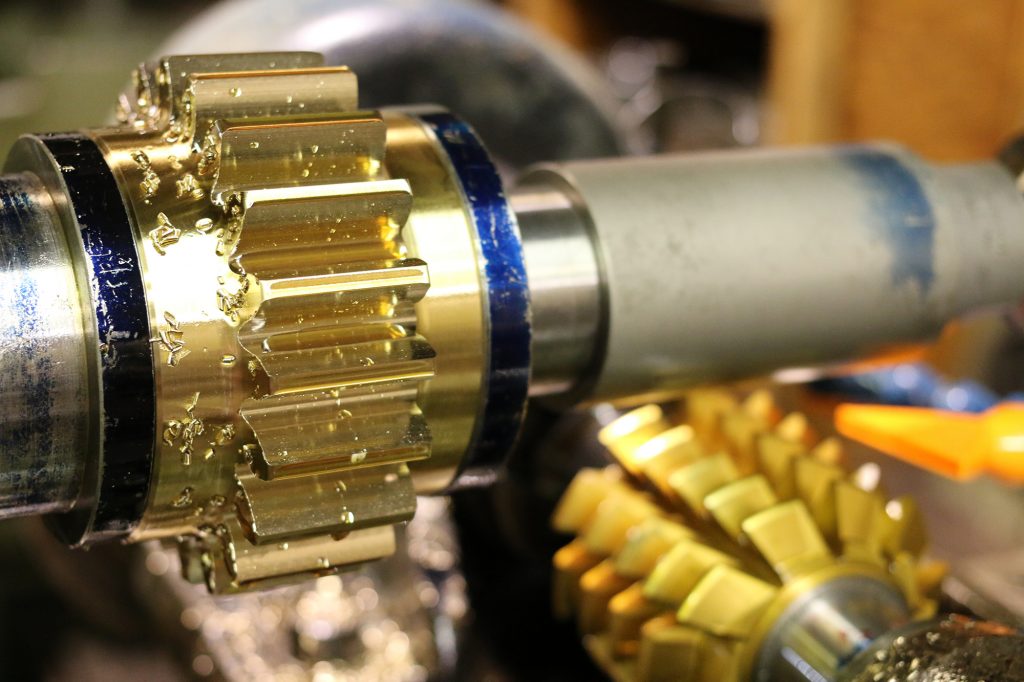

Beyond reverse engineering, B&R’s range of in-house capabilities include turning, gear cutting, heat treating, and grinding.

Beyond reverse engineering, B&R’s range of in-house capabilities include turning, gear cutting, heat treating, and grinding.

“We strive to control the quality of our process by keeping each operation completely in-house,” said Ryan Boxx, B&R’s vice president of manufacturing.

To accommodate that goal, the company has had multiple expansions over the years including the addition of its heat treat facility, steel supply facility, and 40,000-square-foot warehouse for storage and future expansion.

B&R keeps various grades of domestic, alloy steel up to 18″ in diameter in-stock in its material warehouse to reduce lead times.

For gear cutting, B&R has the capacity to manufacture bevel gears from 1″ to 80″ in diameter. High-quality precision parts are cut to AGMA quality standards using an impressive lineup of Gleason equipment.

B&R’s in-house heat treat facility performs a full range of services including annealing (normalizing and stress relieving), quenching, tempering, flame hardening, carburizing, through-hardening, and sub-zero treatment.

B&R’s in-house heat treat facility performs a full range of services including annealing (normalizing and stress relieving), quenching, tempering, flame hardening, carburizing, through-hardening, and sub-zero treatment.

And for the last step in the production process, B&R offers quality assurance. Each job is shipped with a complete inspection report detailing all critical dimensions. Providing the mounting distance, backlash, and photos displaying the correct contact pattern simplifies their customers’ installations.

Even with this wide range of services, Maddox says that they are always looking to grow and expand by adding processes to its current capabilities, whether it is through their own capital investments or partnerships with leading suppliers in the field.

“We pride ourselves, and always have, on our in-house capabilities, from start to finish,” Maddox said. “But there are times we can’t do everything, and in those times, we are fortunate to have partnered with the best suppliers in the industry. Without them, we couldn’t continue to meet our customers’ needs.”

Maddox also stresses the need for more skilled workers in the gear industry.

“There is something to be said for skilled trades,” Maddox said. “And we need to market ourselves in a way that attracts the younger generation to want to be in this industry. Image plays a huge part in it too — how the younger generation sees your company — so keeping up with the digital trends is key.”

“There is something to be said for skilled trades,” Maddox said. “And we need to market ourselves in a way that attracts the younger generation to want to be in this industry. Image plays a huge part in it too — how the younger generation sees your company — so keeping up with the digital trends is key.”

B&R President Nick Sudzum added, “Building upon and adding to the foundation created by my father-in-law, we will continue to strive to exceed the needs of our customers each and every day.”

Sudzum and his team hope to bring another 40 years of success to B&R.

More info www.brgear.com